Autonomous Table Tennis Ball Collecting Robot

Abstract

This work details the design, modeling, control synthesis and experimental validation of two generations of an autonomous differential‑drive robot that detects and centers on a standard 40 mm table tennis ball. A progression from open‑loop servo actuation with proportional / PI guidance to cascaded PI regulation with DC motors and encoder feedback shifts the dominant performance bottleneck from actuation to perception. Sub‑centimeter steady‑state accuracy (≤0.5–1 cm) is achieved on static and slowly rolling targets while maintaining robust stability margins.

- Methodology: Analytical modeling → simulation pre‑tuning → iterative closed‑loop experiments.

- Control Stack: Outer optical guidance (P/PI) + inner wheel speed PI (Prototype 2).

- Measured Margins: Phase ≥ 66°, gain margin → ∞ (speed loop).

- Outcome: Hardware redesign yielded deterministic, bias‑free actuation; perception now rate‑limiting.

Contents

Key Contributions

- Quantified actuator asymmetry prompting drivetrain redesign.

- Identification + first‑order motor model enabling analytical PI tuning.

- Explicit stability margin targets integrated into iteration loop.

- Demonstrated bottleneck migration (actuation → perception) as maturity indicator.

1. Introduction

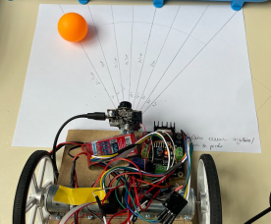

Collecting dispersed table tennis balls between multi‑ball drills breaks training flow. Goal: an autonomous ground robot that rapidly detects, approaches, and centers on a (static or slow rolling) ball, emphasizing accuracy (≤1 cm), speed, and stability (low oscillation).

Development loop: Theory ⇄ Simulation ⇄ Experiment ⇄ Gap analysis ⇄ Improvement.

2. Core Challenge

Core challenge: Fast, precise, robust interception under variable lighting & friction, with constrained onboard compute.

- Reliable ball detection (color, distance ambiguity, lighting)

- Stable, bias‑free navigation

- Low‑latency control pipeline

3. Architecture Overview

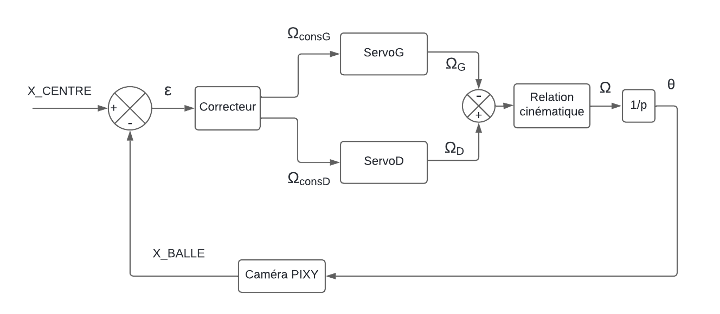

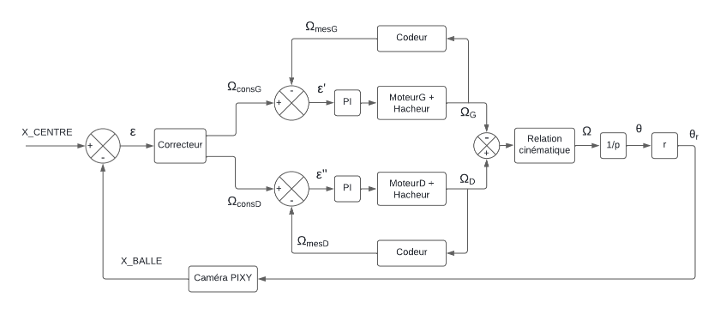

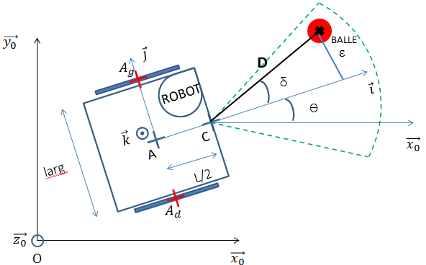

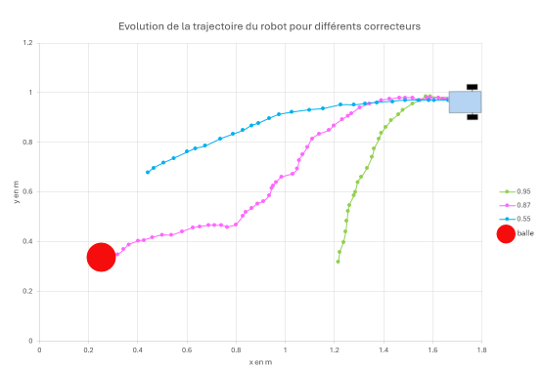

Figure insight (Fig.2–3) Prototype 1 applies the guidance law directly to servos with no wheel‑speed feedback → high sensitivity to servo asymmetry and battery voltage. Prototype 2 adds an inner PI speed loop (encoders) that linearises actuation so the guidance layer manipulates predictable differential speeds, reducing surface‑dependent response variance.

4. Prototype 1: Servo Platform

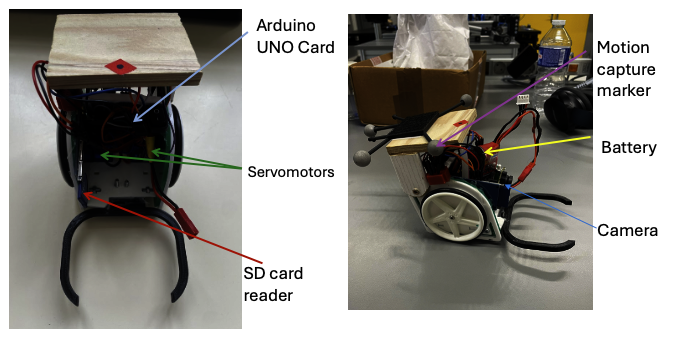

4.1 Hardware Stack

- Camera (color segmentation → centroid)

- Arduino UNO (guidance loop)

- Servomotors (propulsion, asymmetric response)

- Motion capture (ground truth mm‑level)

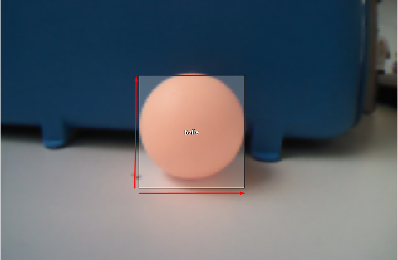

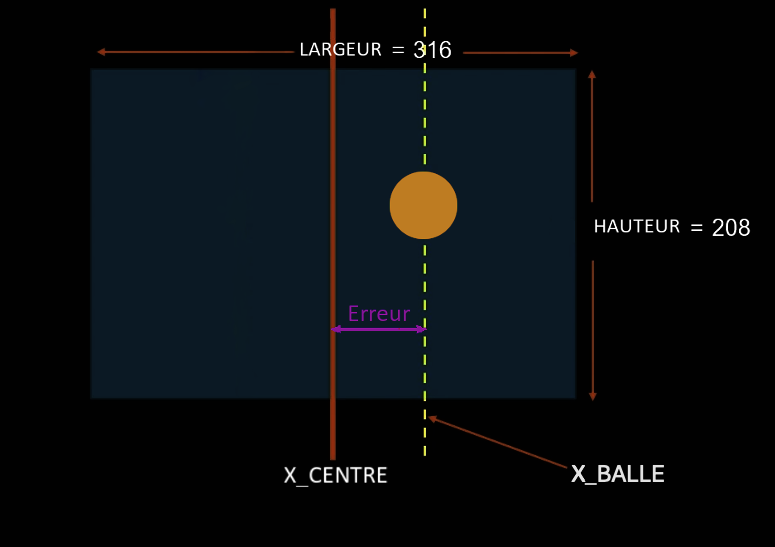

4.2 Vision Bearing Extraction

Processing chain: acquisition → HSV color mask → largest blob → centroid. Horizontal pixel offset becomes bearing error ε. Small‑angle approximation:

Figure insight (Fig.5–6) The vision pipeline keeps only one blob centroid (robust vs clutter). The small‑angle approximation (Eq.1) maps horizontal pixel offset to a near‑linear bearing error—adequate bandwidth without heavy intrinsic calibration at this stage.

Design choice: keep vision minimal (latency & tunability) before richer perception (depth, learning).

4.3 Kinematic Approximation

Differential drive (no‑slip, small heading error):

Used for preliminary gain sweeps (trajectory envelopes & steady‑state error sensitivity).

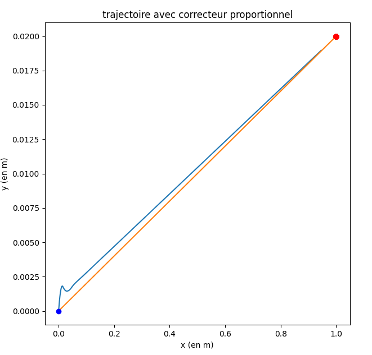

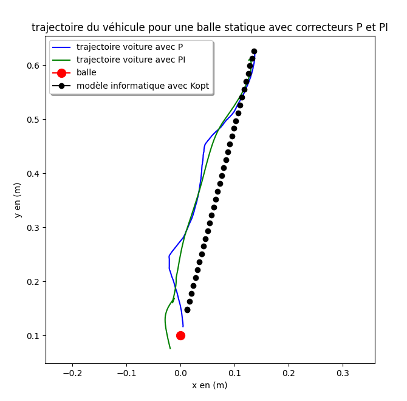

4.4 Baseline P Guidance

Wheel command laws:

Simulation looked stable → direct deployment.

Figure insight (Fig.8–9) Sustained oscillation stems from left/right speed imbalance: the proportional correction repeatedly overshoots because the effective wheel gains differ, injecting a persistent bias. Remedy: add integral action (slow compensation) or redesign actuation.

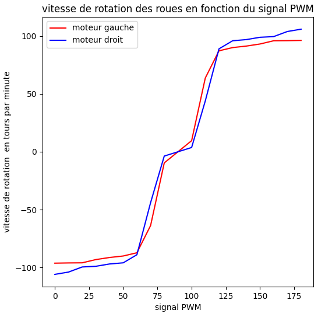

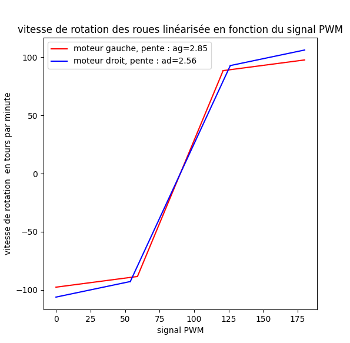

Limitations

Figure insight (Fig.10–11) (10a) Empirical PWM→speed step responses show right servo higher effective gain (+12–15%) and a wider dead zone on the left. (10b) A simplified piecewise‑linear mapping substitutes the raw non‑linear curves inside simulation to preserve bias magnitude while enabling faster analytical gain sweeps. (11) Instrumented rig ensured repeatable capture of the asymmetric dynamics. This structural mismatch drives steady‑state offset under pure P; integral cancels it but increases time in saturation.

Clear unequal speed curves → biased steering & sustained oscillation. Hardware change justified.

4.5 PI Enhancement

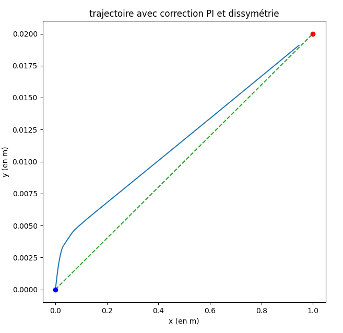

PI guidance controller:

Integral removed residual error at cost of hitting servo speed ceiling.

Figure insight (Fig.12–15) Integral action cancels bias but enlarges the initial saturation interval (command pinned at servo max), slightly extending capture time. The precision vs speed trade now hits the actuator physics ceiling, justifying the hardware redesign.

Findings: error ≤ 0.5 cm; performance now limited by servo saturation & mechanical asymmetry → redesign.

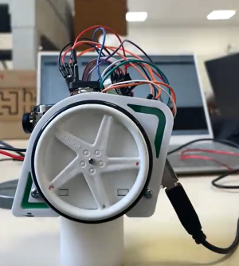

5. Prototype 2: Encoders & Cascaded Control

5.1 Redesign Rationale

Address saturation, asymmetry, and limited camera performance. Shift to a cascaded architecture decoupling velocity regulation from outer guidance.

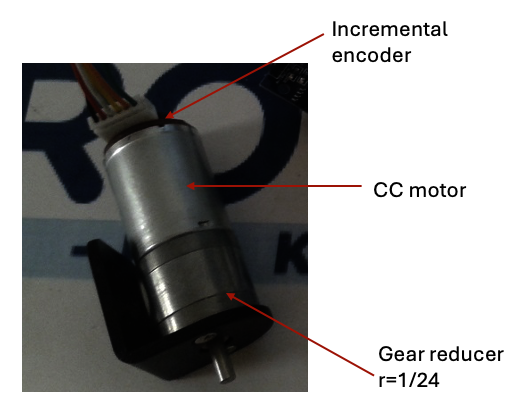

5.2 Actuation & Sensing

- DC motors + 1/24 gearbox (torque & finer speed granularity)

- Incremental encoders (real wheel speed feedback)

- H‑bridge (PWM current delivery)

Result: guidance loop outputs target differential speeds instead of raw PWM → portability to battery & surface variation.

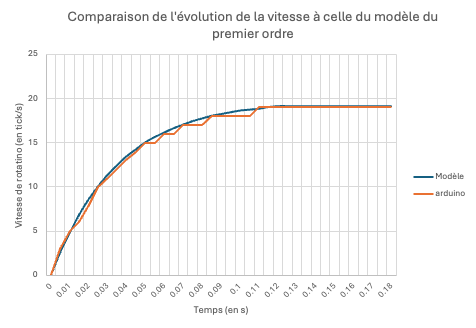

5.3 Motor Model

Step response identification → first order model:

Parameters via least squares fit.

Figure insight (Fig.19) Residual error max < 5% over the operating band → first‑order model sufficient for the speed loop whose goal is mainly slow disturbance rejection (voltage, friction). No immediate derivative term needed.

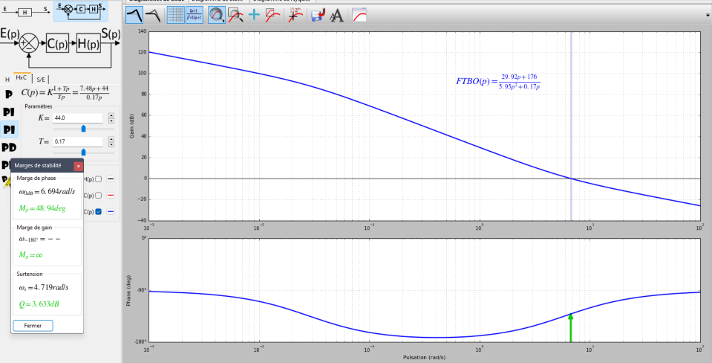

5.4 Speed Loop PI

Speed loop tuning in PySyLic:

Target margins (30 dB / 45°) surpassed by measured (∞ / 66°) → strong robustness.

Figure insight (Fig.20) Design tool reports 66° phase margin (> target 45°) giving robustness to friction variability + vision latency (tens of ms). Infinite gain margin (no crossover) signals low risk of destabilising noise amplification.

Inner loop shields outer guidance from motor & voltage variation.

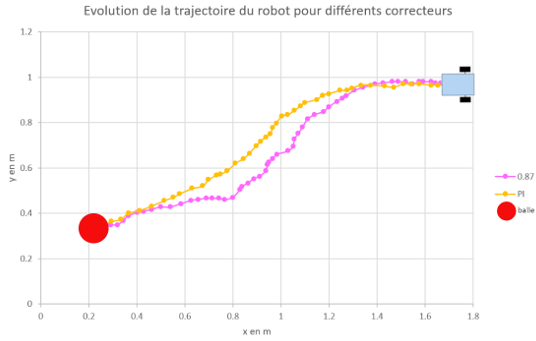

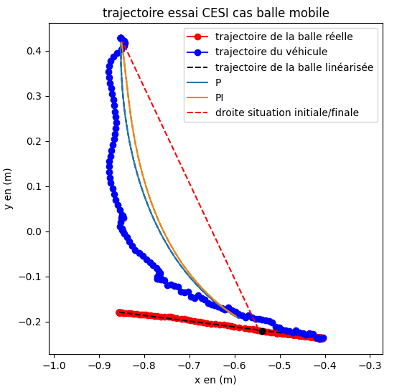

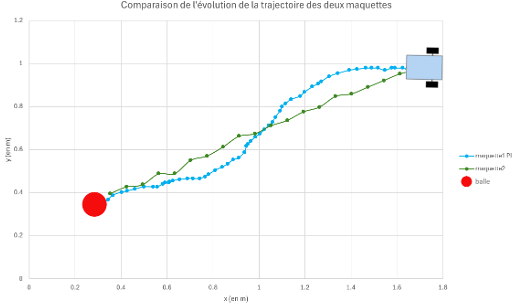

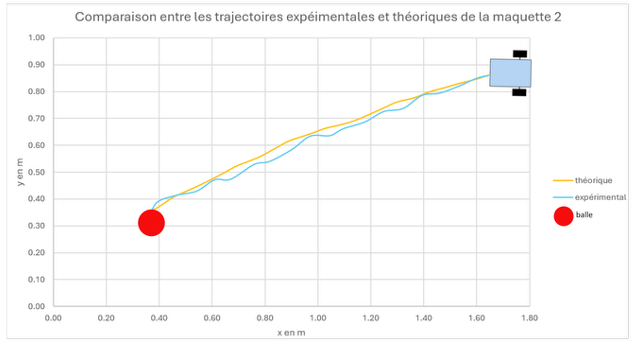

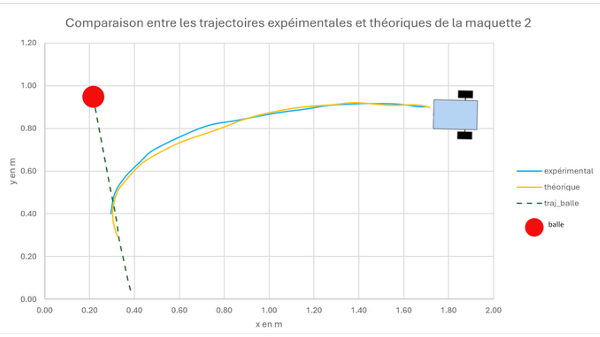

5.5 Comparative Results

Figure insight (Fig.21–23) Prototype 2 both shortens capture time and eliminates terminal oscillation. Remaining model vs experiment gaps come mainly from perception latency + speed discretisation; qualitative dynamics (damping, low overshoot) match, validating the model → controller → hardware pipeline.

Bottleneck migrated: now vision frame rate & lighting noise, not actuation. Classic maturation signal.

6. Prediction vs Measurement

| Stage | Model prediction | Reality | Gap | Action |

|---|---|---|---|---|

| P / servos | Faster, residual error | Oscillations ↑ | Servo asymmetry | Add integral |

| PI / servos | Error removed | Speed capped | Saturation | DC motors + encoders |

| PI / DC motors | Stable & faster | Confirmed | Vision noise | Plan perception upgrade |

7. Minimal Arduino PI Loop

// Encoder reading

int ticksG = readEncoderG();

int ticksD = readEncoderD();

// Speed computation

float omegaG = ticksG / T_sample;

float omegaD = ticksD / T_sample;

// Error

float eG = omegaG_ref - omegaG;

float eD = omegaD_ref - omegaD;

// PI control

uG += Kp * (eG - eG_prev) + Ki * eG * T_sample;

uD += Kp * (eD - eD_prev) + Ki * eD * T_sample;

// Saturation

uG = constrain(uG, 0, 255);

uD = constrain(uD, 0, 255);

// Apply PWM

analogWrite(motorG, uG);

analogWrite(motorD, uD);

// Save errors

eG_prev = eG;

eD_prev = eD;8. Conclusions & Next Focus

Conclusions

- Centimeter‑level convergence across static & rolling targets.

- Structured controller escalation (P → PI → cascaded PI) with measured stability margins.

- Hardware pivot (servos → DC + encoders) justified by quantified asymmetry & saturation.

- Bottleneck intentionally migrated to perception; modeling + tuning pipeline reusable.

Limitations

- Vision latency & lighting sensitivity dominate residual error.

- No derivative / predictive term in guidance yet.

- Energy & thermal envelope not modeled.

Future Improvements

- Perception: depth/stereo or lightweight CNN for robust detection; glare mitigation.

- Control: lead / D action + velocity‑aware gain scheduling.

- Robustness: battery voltage feedforward; IMU fusion between frames.

- Prediction: bounce & rolling decay model for pre‑emptive intercept.

9. Portfolio FAQ

Why switch from hobby servos to DC motors + encoders instead of “better servos”?

Instrumentation exposed persistent gain & dead‑zone asymmetry; moving to encoders + DC motors converted hidden bias into measurable states the controller can regulate.

Hook: steady‑state bias ≈ 0 cm; rare retunes.How was the motor model identified & used?

Recorded step data → least‑squares first‑order fit → analytical PI tuning meeting target margins before hardware deployment, avoiding trial‑and‑error gain hunts.

Hook: first hardware test matched 66° phase margin design.What is the next performance lever?

Perception latency & noise now dominate; roadmap: faster capture/processing, illumination normalization, optional lightweight depth to anticipate motion.

Hook: capture time reductions now vision‑bound.